Torsion Springs Information

Stock or custom….we provide the springs you need…

The helix design of torsion springs exerts torque or rotary force. Torsion springs attach to other components at the ends so that as the components rotate around the center of the spring, the spring pushes them back to their initial position. Contrary to what the name suggests, torsion springs are subject to stress from bending rather than stress from torsion. Torsion springs store and release angular energy. They also can hold a mechanism in place by deflecting the legs across the centerline axis of its body.

Torsion springs are designed and coiled to be actuated rotationally and to supply an angular return force. Many leg configuration options mean that torsion springs can be attached in multiple ways. Leg options for torsion springs include leg angle, equal leg length, and leg end style. Leg end style options include straight torsion, straight offset, hinged, short hook ends, and hook ends. Torsion spring ends can be hooked, looped, bent, or twisted to meet application needs. Torsion springs are commonly used in swing-down tailgates, garage doors, lever returns and more. Small torsion springs are used in clothes pins, clipboards, and electronic devices.

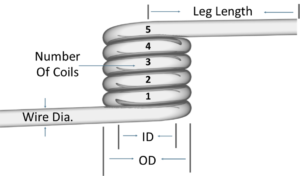

Torsion spring parameters include:

- Outer diameter of the spring

- Wire diameter of the wire used to create the spring

- Total coils -number of active coils plus the end coils

- Leg length – length of non-coiled spring ends

- Deflection angle – the movement of spring ends under the application or removal of an external load

- Direction of wind – left or right hand

- Material – torsion springs are constructed from music wire, hard drawn, stainless steel, phosphor bronze, and more.

W.B. Jones offers an extensive selection of stock torsion springs as well as full capabilities and experience in creating custom torsion springs. For fast, personal assistance, please give us a call at 859-581-7600. We look forward to working with you.