Extension Springs Information

Extension springs are commonly used in automotive mechanisms, garage doors, trampolines, washing machines, tools, toys, and equipment in a wide array of industries. Extension spring ends are designed to meet specific application needs. Configurations include hooks, threaded inserts, extended twist loops, crossover center loops, expanded eyes, reduced eyes, rectangular ends and teardrop-shaped ends. Another extension spring configuration features a drawbar spring. In this design, the load at the ends of long, steel loops that pass through the spring center and compress the spring upon loading.

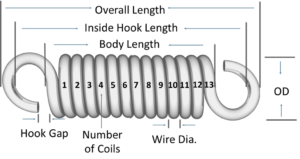

Extension spring parameters include:

- Outer diameter- of the spring

- Wire diameter – of the wire used to create the spring

- Overall length – of the spring in the unloaded position

- Rate – amount of weight required to deflect the spring one inch

- Load -amount of weight the spring can carry when deflected to a given height

- Material – compression springs are constructed from stainless steel, music wire, hard drawn, brass, and more.

W.B. Jones offers an extensive selection of stock extension springs as well as full capabilities and experience in creating custom extension springs. For fast, personal assistance, please give us a call at 859-581-7600. We look forward to working with you.